Styrene butadiene rubber (SBR) — also known as red rubber — is a synthetic copolymer of styrene and butadiene with characteristics that are very similar to those of natural rubber. It makes an excellent gasket material due to its good physical properties, such as tensile strength, abrasion resistance, and low-temperature flexibility.

This article will discuss everything you need to know about SBR gaskets, including their material properties, benefits, and applications.

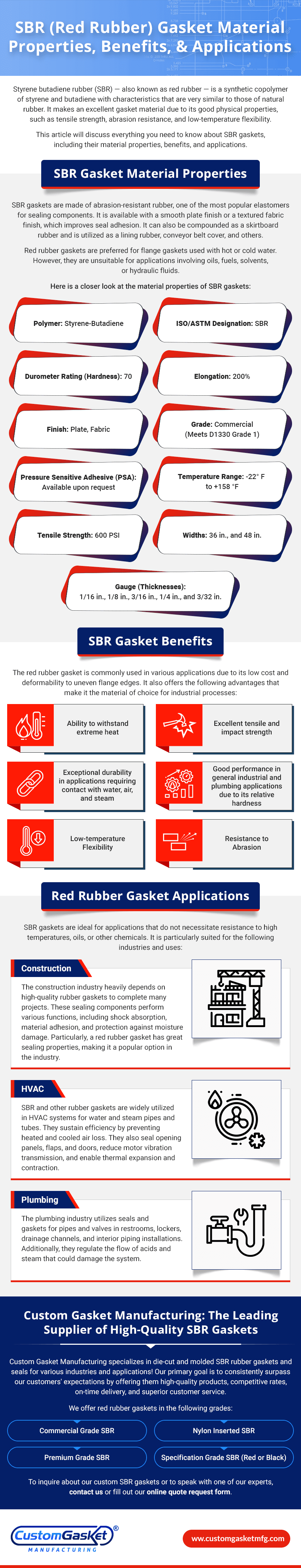

SBR Gasket Material Properties

SBR gaskets are made of abrasion-resistant rubber, one of the most popular elastomers for sealing components. It is available with a smooth plate finish or a textured fabric finish, which improves seal adhesion. It can also be compounded as a skirtboard rubber and is utilized as a lining rubber, conveyor belt cover, and others.

Red rubber gaskets are preferred for flange gaskets used with hot or cold water. However, they are unsuitable for applications involving oils, fuels, solvents, or hydraulic fluids.

Here is a closer look at the material properties of SBR gaskets:

- Polymer: Styrene-Butadiene

- ISO/ASTM Designation: SBR

- Durometer Rating (Hardness): 70

- Elongation: 200%

- Finish: Plate, Fabric

- Gauge (Thicknesses): 1/16 in., 1/8 in., 3/16 in., 1/4 in., and 3/32 in.

- Grade: Commercial (Meets D1330 Grade 1)

- Pressure Sensitive Adhesive (PSA): Available upon request

- Temperature Range: -22° F to +158 °F

- Tensile Strength: 600 PSI

- Widths: 36 in., and 48 in.

SBR Gasket Benefits

The red rubber gasket is commonly used in various applications due to its low cost and deformability to uneven flange edges. It also offers the following advantages that make it the material of choice for industrial processes:

- Ability to withstand extreme heat

- Excellent tensile and impact strength

- Exceptional durability in applications requiring contact with water, air, and steam

- Good performance in general industrial and plumbing applications due to its relative hardness

- Low-temperature flexibility

- Resistance to abrasion

Red Rubber Gasket Applications

SBR gaskets are ideal for applications that do not necessitate resistance to high temperatures, oils, or other chemicals. It is particularly suited for the following industries and uses:

Construction

The construction industry heavily depends on high-quality rubber gaskets to complete many projects. These sealing components perform various functions, including shock absorption, material adhesion, and protection against moisture damage. Particularly, a red rubber gasket has great sealing properties, making it a popular option in the industry.

HVAC

SBR and other rubber gaskets are widely utilized in HVAC systems for water and steam pipes and tubes. They sustain efficiency by preventing heated and cooled air loss. They also seal opening panels, flaps, and doors, reduce motor vibration transmission, and enable thermal expansion and contraction.

Plumbing

The plumbing industry utilizes seals and gaskets for pipes and valves in restrooms, lockers, drainage channels, and interior piping installations. Additionally, they regulate the flow of acids and steam that could damage the system.

Custom Gasket Manufacturing: The Leading Supplier of High-Quality SBR Gaskets

Custom Gasket Manufacturing specializes in die-cut and molded SBR rubber gaskets and seals for various industries and applications! Our primary goal is to consistently surpass our customers’ expectations by offering them high-quality products, competitive rates, on-time delivery, and superior customer service.

We offer red rubber gaskets in the following grades:

- Commercial Grade SBR

- Nylon Inserted SBR

- Premium Grade SBR

- Specification Grade SBR (Red or Black)

To inquire about our custom SBR gaskets or to speak with one of our experts, contact us or fill out our online quote request form.